Say Goodbye to Glare: The Essential Garmin Nav 6 Anti-Reflective Film

With the Garmin Nav 6 Anti-Reflective Film, you can say goodbye to shading a screen in harsh sunlight

Why do you need ITO Plastic?

ITO (Indium Tin Oxide) is an electrically conductive substance that is also optically clear, making it useful for a variety of applications. Initially, ITO could only be applied to glass as a thin coating. The deposition temperature of 190° C required was clearly not suitable for plastic.

Diamond Coatings have worked on a solution to this, applying years of research and cutting-edge technology – we are now able to offer our ITO coatings to a range of plastics.

Why ITO Plastic?

There is a school of thought that glass is great but plastic is greater. With greater impact resistance as well as being lighter and more cost effective to produce, ITO plastic has a lot going for it.

Because of the above, ITO plastic is now widely used in a variety of applications, from retail stores to outer space. With impressive peak light transmission and shielding effectiveness (RFI and EMI), Indium Tin Oxide plastic is now used commonly in the production of touch screens (for retail outlets, ATM machines, medical and military instruments as good examples).

ITO plastic applications include heated optically clear (transparent) display filters, photovoltaic cells, EMI/RFI shielding, electrostatic dissipation and more.

Indium Tin Oxide Coated Plastic Options

Diamond Coatings ITO Plastic

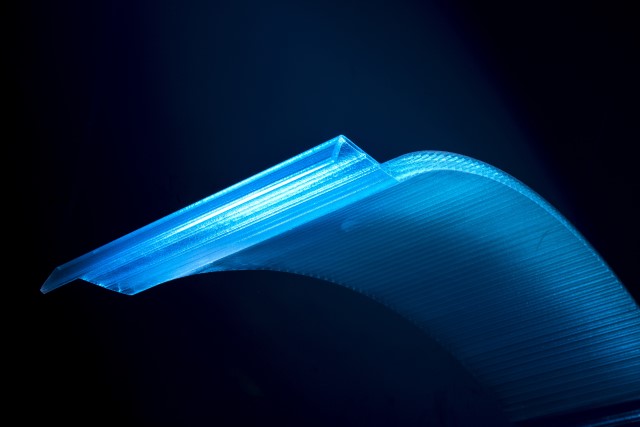

Diamond Coatings has designed and built its own plant for the production of ITO coated plastic. Carried out in a vacuum at low temperatures, the process allows coating of plastic substrates. The flexible substrate handling system enables coating of flat, curved and varying injection moulded shapes.

Diamond Coatings’ plant has the ability to produce ITO plastic of up to 1000 mm by 1000 mm in size with sheet resistances ranging from 8 to 1000 Ohms/sq.

The ITO plastic coating can be applied with anti-glare properties and additional scratch resistant properties if required. If you have any requirements for ITO plastic, please get in touch, we would be happy to hear from you.

With the Garmin Nav 6 Anti-Reflective Film, you can say goodbye to shading a screen in harsh sunlight

At Diamond Coatings, we provide the foundational transparent conductive coatings that make these advanced switches possible

At Diamond Coatings, we specialise in turning ordinary glass into high-performance heated windows

As a leading name among ITO companies, Diamond Coatings doesn’t just supply standard coatings; we engineer bespoke solutions that push boundaries

If you are interested in any of our products or services, please use the contact form or give us a call, we will be happy to discuss how we may be able to help you.