How To Achieve Smudge-Resistant Surfaces

Anti-fingerprint coatings create a barrier against everyday marks, ensuring that your devices, and other surfaces, remain pristine and clear.

Diamond Coatings specialise in the design and manufacture of ITO Heater Windows on both glass and plastic substrates.

The optimal performance of LCD displays is very much dependant on temperature and therefore in low temperatures or very cold environments they can suffer from low response times and a possible loss of functionality.

Diamond Coatings offer a well establish Transparent heated window solution using Transparent Conducting Oxide Coatings to maintain the optimal performance of your displays even in the most demanding operating environments.

Typical applications of Transparent ITO Heaters operating in harsh environments:

Diamond Coatings can offer full design assistance to determine the required parameters to achieve all targeted performance criteria in relation to both the heater functionality and optical performance of your application.

ITO Coatings can be vacuum deposited in Diamond Coatings state of the art vacuum coating plants to any sheet resistance from as low as 2.5 Ohms/Sq, transparent ITO Heaters can therefore be designed specifically for the required area to be heated. The optimum conductive ITO coating sheet resistance and thickness is calculated to achieve the required power density that will provide optimal heating uniformity and the best possible light transmission and optical performance.

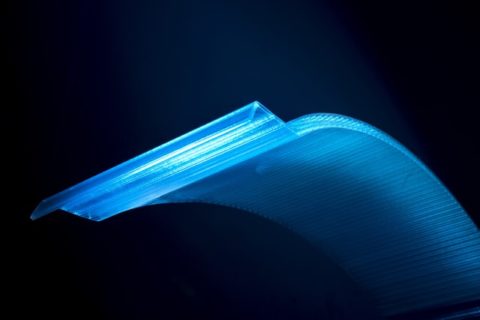

Transparent Heater Windows can be designed and vacuum deposited onto both flat and curved substrates. Diamond Coatings can also vacuum deposit ITO Coatings for both heater and EMC functionality onto glass or polycarbonate domes.

In addition to their primary heating functionality, Transparent ITO Heaters on both glass and plastic substrates can be further enhanced to provide additional coatings for EMC Filters and Anti-Reflection Coatings or Index-Matched coatings to further reduce reflection and optimise greater still the optical performance of the application.

Diamond Coatings can offer a range of Silver Busbar connection options including for glass substrates, a highly durable fired in silver frit busbar to which it is also possible to solder connection wires.

Additional aesthetics requirements can be provided with full capabilities to provide decorative borders, any required logo or additional graphics.

Contact Diamond Coatings today for a quotation and design assistance with your Transparent Heater application requirements.

Anti-fingerprint coatings create a barrier against everyday marks, ensuring that your devices, and other surfaces, remain pristine and clear.

At Diamond Coatings, we take pride in being a leading TCO films supplier, specialising in the deposition of high-quality ITO.

At Diamond Coatings, we’re passionate about pushing the boundaries of touch technology. We’re not just manufacturers – we’re innovators

Let’s take a closer look at electrically conductive plastics and explore how we utilise Indium Tin Oxide (ITO) coating technology to unlock their potential.

If you are interested in any of our products or services, please use the contact form or give us a call, we will be happy to discuss how we may be able to help you.