Polyester Film UK: The Versatile Solution for Demanding Applications

At Diamond Coatings, we enhance the capabilities of polyester film by applying our specialised ITO coatings, creating a material that’s truly fit for the future.

What is a capacitive coating?

Picture this: you’re holding a sleek smartphone, fingers dancing effortlessly across its smooth surface, summoning apps and information with a mere touch. What enables this seemingly magical interaction between your touch and the device’s response? In a nutshell, capacitive coatings.

At the heart of modern touch-sensitive screens lies a technology as transparent as it is powerful: capacitive coatings. These coatings, primarily composed of Indium Tin Oxide (ITO), possess a remarkable dual nature—they remain transparent while conducting electricity. It’s this unique property that propels them into the spotlight, empowering various everyday devices we often take for granted.

So, what exactly is a capacitive coating? In essence, it’s a specialised layer, often applied to surfaces like glass, polymers, or even ceramics, designed to detect and respond to touch or proximity.

The secret sauce? The conductive capabilities of ITO embedded within these coatings. Capacitive coatings provide a layer of conductivity across a surface that has been coated. The conductivity reacts when human touch is applied as the touch disrupts the charge – this enables a device to determine precise location and gesture of touch, offering a seamless and intuitive user experience.

Take, for instance, the commonly used smartphone screens. These sleek, responsive panels owe their functionality to capacitive coatings. As your fingertip bridges these fields, the capacitance alters, triggering the device to register and react accordingly. It’s this invisible dance between touch and technology that grants us the privilege of effortlessly navigating our touch enabled devices.

But the scope of capacitive coatings goes beyond our handheld companions. They find applications in an array of industries and products, elevating functionality and user experience. From interactive kiosks and ATMs to sophisticated medical devices and automotive touch interfaces, the reach of capacitive coatings extends far beyond our smartphones.

In the automotive realm, capacitive coatings enhance user interfaces within vehicles, enabling responsive touchscreens for infotainment systems, internal lighting, climate controls, and navigation interfaces. This integration not only offers a futuristic driving experience but also prioritises safety by allowing drivers to interact seamlessly with these interfaces.

Capacitive coatings have woven their way into the fabric of healthcare technology. From medical equipment interfaces to diagnostic devices, these coatings facilitate swift and precise interactions, empowering healthcare professionals to focus on patient care without technological hindrances.

But let’s not forget about the ever-expanding horizons of home automation. Smart home panels, interactive displays, and appliances are integrated with capacitive coatings, transforming living spaces into interconnected hubs of convenience and efficiency. Imagine effortlessly adjusting lighting, temperature, or entertainment systems with a simple touch.

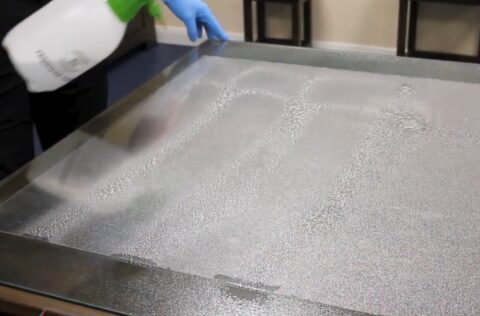

The manufacturing process behind capacitive coatings involves sophisticated deposition techniques where the application of ITO onto substrates occurs with meticulous attention to detail. The result? Thin, invisible layers that possess the dual qualities of transparency and conductivity—a technological fusion that unlocks a world of possibilities.

It is very fair to say that capacitive coatings, fuelled by the unassuming yet powerful presence of ITO, redefine how we engage with technology. They have made surfaces responsive to touch commands, transforming them into interactive gateways that bridge our physical and digital worlds.

If you require a capacitive coatings service, we are market leaders with decades of specialist coatings behind us. Get in touch with us today to discuss your needs – we would be delighted to assist.

At Diamond Coatings, we enhance the capabilities of polyester film by applying our specialised ITO coatings, creating a material that’s truly fit for the future.

At Diamond Coatings, we understand the critical role that projection booth glass plays in delivering a truly immersive cinematic experience

We wanted to highlight the exceptional value now available on our VISIN discounted PPE Face Shields, offering you industry-leading protection and clarity

Have you ever wondered how to achieve crystal-clear visuals and reduce annoying reflections on your displays, windows, or touch panels?

If you are interested in any of our products or services, please use the contact form or give us a call, we will be happy to discuss how we may be able to help you.