Polyester Film UK: The Versatile Solution for Demanding Applications

At Diamond Coatings, we enhance the capabilities of polyester film by applying our specialised ITO coatings, creating a material that’s truly fit for the future.

What Are Optical Thin Film Coatings?

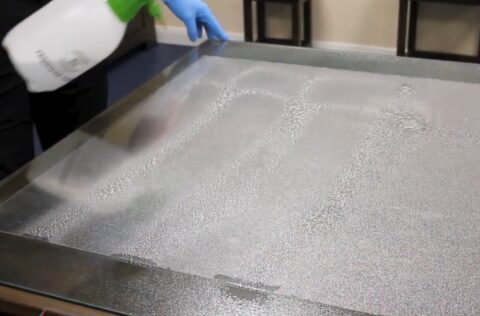

Optical thin film coatings are essentially used to alter a material’s optical properties – namely changing the reflectance and transmittance properties to the substrate to which it has been applied.

A basic optical thin film coating will normally be made up from a single layer, with other more complicated applications requiring further layers. The selected number of layers and type of coating influence surface reflectivity over specific wavelengths and angles of incidence.

The more complicated, multi-layered thin film coatings enable more variety to incident angles and different wavelengths. Nearly all optical components utilise some form of thin film optical coating before it can be used properly in its intended application.

So where are optical thin film coatings used?

The applications are numerous. As we mentioned above, nearly all optical components need a thin film coating to properly execute the task they have been built for. Common areas that utilise these thin film coatings for optical components include aerospace. medical and military, the entertainment industry (cinema projectors and movie cameras, as examples) and any imaging applications, including microscopy.

Diamond Coatings optical thin film coatings

Using semiconductor and oxide layers with an approximate wavelength range of between 300 nm and 20 microns, Diamond Coatings supply an extensive range of special thin film optical coatings within the visible & infra-red (IR) regions of the light spectrum.

Available on a diversity of optical polymers, glasses and sapphire, our special optical coatings can be supplied in visible, near-IR and IR wavelength ranges and include, for example:

Providing average reflectance below 0.5% over a broad wavelength range (UV, visible & IR regions), our broadband multi-layer AR coatings can be designed for a diversity of substrates, incidence angles, wavelengths and performances. Our capabilities also extend to the design of dual-band AR coatings.

Typically used within applications involving specific laser wavelengths, our V coat anti-reflective coatings can be produced for diverse incidence angles. At single wavelengths, it is possible to achieve reflections below 0.1%.

Get In Touch

Please contact our technical experts today for more detailed information on different types of special optical coating and/or discuss your specific application’s exact requirements.

At Diamond Coatings, we enhance the capabilities of polyester film by applying our specialised ITO coatings, creating a material that’s truly fit for the future.

At Diamond Coatings, we understand the critical role that projection booth glass plays in delivering a truly immersive cinematic experience

We wanted to highlight the exceptional value now available on our VISIN discounted PPE Face Shields, offering you industry-leading protection and clarity

Have you ever wondered how to achieve crystal-clear visuals and reduce annoying reflections on your displays, windows, or touch panels?

If you are interested in any of our products or services, please use the contact form or give us a call, we will be happy to discuss how we may be able to help you.