Polyester Film UK: The Versatile Solution for Demanding Applications

At Diamond Coatings, we enhance the capabilities of polyester film by applying our specialised ITO coatings, creating a material that’s truly fit for the future.

Touch Screen Technology

Where would we be without touch screen technology these days? In today’s modern world, it’s quite possibly near impossible to get through a single day without using a touch screen – from your phone, through to ATMs and supermarket checkouts.

And that’s just for everyday people. Touch screen technology is utilised in many different working environments, from factories, hospitals and science laboratories, as well as all forms of travel, including aviation, marine and even space exploration – not to mention the standard car dashboard.

In short, touch screen technology is all around us and is used continuously daily.

How Does Touch Screen Technology Work?

One of the most common forms of touch screens is the capacitive touch screen. This works by the surface of the screen identifying a users touch and the precise location of the touch. A capacitive screen is almost usually glass fronted. I guess this doesn’t really explain how the glass identifies a touch or gesture, such as a swipe or pinch, but by applying a very special thin coating, the glass can pick up the touch.

What is this special coating?

A lot of capacitive screens use an ITO (Indium Tin Oxide) coating. ITO is transparent (useful for glass) and also (clever bit) electrically conductive. If you can imagine that the entire glass surface can carry a charge, you are nearly there.

When a user touches the glass, the charge is changed – and changed at that specific location – and as a result, the unit holding the glass can react to the information provided by the touch or gesture accordingly.

Indium Tin Oxide is used in a huge number of differing applications, not just for touch screens. Automotive, Aerospace & Entertainment, Medical, Imaging & Microscopy, Research & Development, Space, Military & Defence and much more (You can read about the uses of Indium Tin Oxide more extensively here).

Indium Tin Oxide can also be applied to thin films and plastics – so yes, you can actually have electrically conductive plastic too!

Diamond Coatings Touch Screen Technology

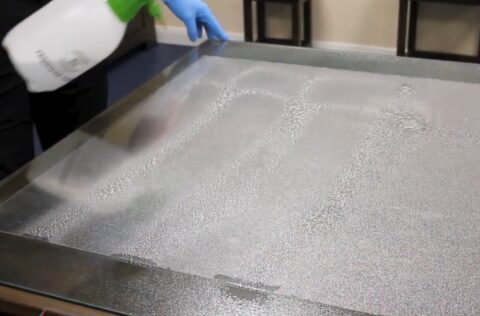

Diamond Coatings can provide anything from development to production volumes for all kinds of capacitive touch screens.

The screens can also be provided with anti-glare and other finishes as required and produced on glass or plastic (flexible or rigid). Our touch screens are available in sizes up to 1,000 mm x 1,000 mm.

How can we help?

For additional information on Diamond Coatings touch screens or to discuss your specific project requirements, please contact us or e-mail: enquiries@diamondcoatings.co.uk now.

At Diamond Coatings, we enhance the capabilities of polyester film by applying our specialised ITO coatings, creating a material that’s truly fit for the future.

At Diamond Coatings, we understand the critical role that projection booth glass plays in delivering a truly immersive cinematic experience

We wanted to highlight the exceptional value now available on our VISIN discounted PPE Face Shields, offering you industry-leading protection and clarity

Have you ever wondered how to achieve crystal-clear visuals and reduce annoying reflections on your displays, windows, or touch panels?

If you are interested in any of our products or services, please use the contact form or give us a call, we will be happy to discuss how we may be able to help you.