How To Achieve Smudge-Resistant Surfaces

Anti-fingerprint coatings create a barrier against everyday marks, ensuring that your devices, and other surfaces, remain pristine and clear.

What is transparent conductive oxide used for?

It is probably a good idea to start with the question ‘What is a transparent conductive oxide’? In abbreviated form, it is known as a TCO, a transparent conductive oxide can be deposited onto a surface, providing a clear (transparent) coating which is also electronically conductive.

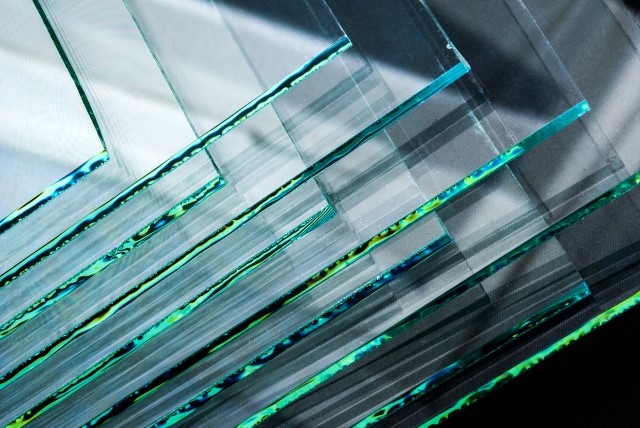

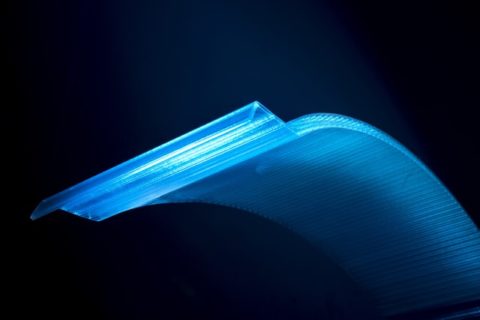

These surfaces (known as substrates) include glass, plastic and other materials. If you’re wondering why glass or plastic would ever need to be conductive, read on…

Transparent conducting oxides (TCO) are used in a variety of applications. The first TCO ever used, Cadmium Oxide, was utilised in solar cells in the early 1900’s. These days, the most widely used TCO is Indium Tin Oxide (ITO). ITO is considered the ‘premier’ of all TCOs. Diamond Coatings are also considered by many to be the ‘premier’ supplier of ITO coatings in the UK and indeed globally.

So what is transparent conductive oxide used for?

Put it this way, you have today probably encountered a device or application that utilises transparent conductive oxides in some manner. Transparent contacts for solar cells, optoelectronic devices, low-e (smart) windows and glass, EMI shielding and photovoltaics are just some examples that utilise TCOs. Some Liquid Crystal Displays will also use transparent conductive oxides.

Why use transparent conductive oxides?

The need for an electrically conductive yet clear coating in the above is immediately obvious in some cases. Low energy smart windows with TCO coatings can see a reduction in energy usage of up to 30%, which is pretty amazing (and makes you wonder why smart windows are not more prevalent maybe).

The most common use of transparent conductive oxides?

A more common usage that you may be more familiar with is in touch related devices. Using either resistive touch or capacitive touch mechanics, ITO coatings assist in the touch sensor element of these devices.

In the majority of public facing touch driven screens (ATMs, ticket machines…), a thin film with an ITO coating under the screen determines the location of the touch by recognising the downward pressure on the screen. There is a change in charge on an x-y grid where the pressure is applied. This is known as resistive touch. Resistive touch screens are also widely used in the medical and military industries due to their robustness.

Smartphones, tablets and touch screen PCs use ITO coating in a different way – the surface of the screen is coating in ITO, making the screen electronically conductive. A human touch will alter the charge at the point of touch. This system (capacitive touch) is particularly useful for phones and tablets as the change in charge can determine not only the location of touch, but multiple touches as well as gestures (pinching and swiping for instance).

Need more information?

If you would like to know more about transparent conductive oxides, or more specifically our ITO coatings at Diamond Coatings, please get in touch, we would be happy to hear from you.

Anti-fingerprint coatings create a barrier against everyday marks, ensuring that your devices, and other surfaces, remain pristine and clear.

At Diamond Coatings, we take pride in being a leading TCO films supplier, specialising in the deposition of high-quality ITO.

At Diamond Coatings, we’re passionate about pushing the boundaries of touch technology. We’re not just manufacturers – we’re innovators

Let’s take a closer look at electrically conductive plastics and explore how we utilise Indium Tin Oxide (ITO) coating technology to unlock their potential.

If you are interested in any of our products or services, please use the contact form or give us a call, we will be happy to discuss how we may be able to help you.