Polyester Film UK: The Versatile Solution for Demanding Applications

At Diamond Coatings, we enhance the capabilities of polyester film by applying our specialised ITO coatings, creating a material that’s truly fit for the future.

Diamond monolithic RFI shielded filters are custom optical filters produced by direct deposition of thin transparent and electrically conductive coatings onto a diversity of flat or profiled substrates. Here’s everything you need to know about these RFI shielded optical filters.

Measured by use of independent (MIL-STD-285 compliant) test methods, our monolithic filters’ RFI/EMI shielding effectiveness ranges between 58dB and 26dB at 1MHz and 1GHz respectively.

In terms of spectral properties, light transmission rates depend on both the type of substrate used and the surface finish thereof.

Typical peak light transmission rates (at wavelengths ranging between 525 nm and 600nm) for 20 ohms/sq. coatings on glass with standard and index-matched Diamox coatings, for example, are 87% and 92% respectively.

For 50 ohms/sq. coatings on transparent hard-coated polycarbonate substrates, the respective typical peak light transmission rates for the standard and index-matched Diamox coatings at the same wavelength range are 85% and 89%.

Combining these properties with improved mechanical and environmental stability (in comparison to laminated or edge-bonded filters), Diamond Coating’s RFI shielded optical filters are perfect for electronic display/communications applications in industries including, for example:

Diamond Custom Optical Filters

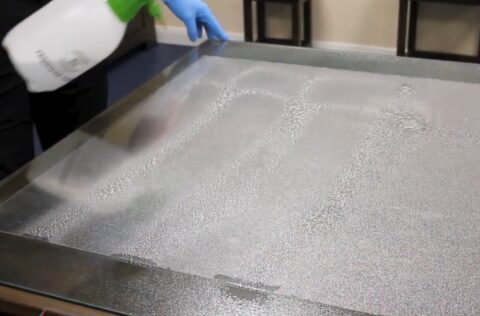

Using purpose-designed, state-of-the-art coating technology/facilities, Diamond Coatings can produce both flat and profiled monolithic filters on a broad range of substrates including polycarbonates, acrylic and glass with varying surface finishes:

Surface finishes depend on requirements and may, for instance, consist of etched glass, hard (non-glare) coatings on polycarbonates and/or Diamox+ AR (anti-reflective) coatings.

Diamond RFI/EMI shielded monolithic filters may be terminated with silver bus bars or copper tapes, which may be carried around to front surfaces. Use of fabric over foam and conductive silicone gaskets is also possible.

Contact us by telephone: +44 (0) 121 550 9430/+44 (0) 8451 360 603; email or via our contact form now to learn more about our custom optical filters and/or discuss the most viable substrate, surface finish, sheet resistance & termination options for your specific application with one of our helpful technical experts.

At Diamond Coatings, we enhance the capabilities of polyester film by applying our specialised ITO coatings, creating a material that’s truly fit for the future.

At Diamond Coatings, we understand the critical role that projection booth glass plays in delivering a truly immersive cinematic experience

We wanted to highlight the exceptional value now available on our VISIN discounted PPE Face Shields, offering you industry-leading protection and clarity

Have you ever wondered how to achieve crystal-clear visuals and reduce annoying reflections on your displays, windows, or touch panels?

If you are interested in any of our products or services, please use the contact form or give us a call, we will be happy to discuss how we may be able to help you.