Polyester Film UK: The Versatile Solution for Demanding Applications

At Diamond Coatings, we enhance the capabilities of polyester film by applying our specialised ITO coatings, creating a material that’s truly fit for the future.

Lightweight, pliable, transparent and boasting outstanding impact and heat resistance, polycarbonate makes an excellent alternative to glass in many ‘robust’ applications. Unfortunately, it somewhat lacks in scratch resistance. This can, however, be easily remedied with Diamond Coatings’ polycarbonate scratch resistant coating.

Coated with anti -reflective and/or conductive ITO coatings, polycarbonate makes an excellent substrate for applications including, for example:

Typical Transparent ITO Heater applications used within somewhat unforgiving environments may, for example, include:

AR coated polycarbonate’s high impact resistance also makes it the perfect choice for anti-vandal (public information displays, ATMs, etc.) touch screens, as well as bullet resistance lamination.

Other Polycarbonate Applications

Not only reducing unwanted reflection/glare but also protecting underlying images against fading and yellowing caused by UV, AR coated polycarbonate is also a highly popular choice for applications like, for instance:

Naturally, the ‘heavy duty’ use in many of these applications makes it necessary for the polycarbonate substrates to offer reasonable resistance to scratching. This is where Diamond Coatings’ hard coat options come into play.

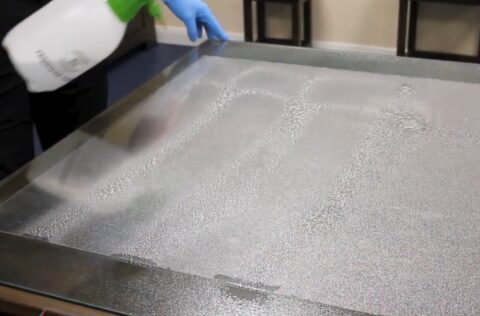

In addition to producing a comprehensive range of anti-reflective, conductive ITO/Index Matched ITO and many special optical coatings, Diamond Coatings also offer application of hard coat coatings designed to increase substrates’ scratch and/or chemical resistance.

Often designed specially to meet specific client requirements, our hard coat options significantly increase the strength, scratch/chemical resistance and subsequently durability, of applications exposed to heavy use and/or harsh environments.

Contact us on +44 (0) 121 550 9430 or +44 (0) 8451 360 603 (Local Rate) today to learn more about available hard coat/polycarbonate scratch resistant coating options.

At Diamond Coatings, we enhance the capabilities of polyester film by applying our specialised ITO coatings, creating a material that’s truly fit for the future.

At Diamond Coatings, we understand the critical role that projection booth glass plays in delivering a truly immersive cinematic experience

We wanted to highlight the exceptional value now available on our VISIN discounted PPE Face Shields, offering you industry-leading protection and clarity

Have you ever wondered how to achieve crystal-clear visuals and reduce annoying reflections on your displays, windows, or touch panels?

If you are interested in any of our products or services, please use the contact form or give us a call, we will be happy to discuss how we may be able to help you.