Polyester Film UK: The Versatile Solution for Demanding Applications

At Diamond Coatings, we enhance the capabilities of polyester film by applying our specialised ITO coatings, creating a material that’s truly fit for the future.

Optical Coating Technology

Diamond Coatings is a company at the forefront of a revolution in optical coating technology. We utilise cutting-edge processes to craft exceptional coatings that enhance the performance and durability of various optical components. Two of our key applications are anti-reflective (AR) coatings and Indium Tin Oxide (ITO) coatings.

Optical coatings are specialised thin films deposited onto an optical surface to manipulate how light interacts with it. These coatings can enhance light transmission, reflection, or absorption, leading to improved functionality and performance in various optical applications.

Diamond Coatings utilises advanced materials and processes to create coatings that offer significant advantages:

Anti-Reflective Coatings

Anti-reflective (AR) coatings are a cornerstone of optical coating technology. By minimising unwanted reflections on optical surfaces, AR coatings allow for increased light transmission, resulting in sharper images, improved contrast, and enhanced overall performance.

Diamond Coatings’ advanced technology allows for high-performance AR coatings. Here’s a breakdown of the benefits:

AR Coatings for PET Films

Traditionally, AR coatings have been primarily used on glass substrates. However, Diamond Coatings’ technology has opened doors for their application on PET films. This advancement is particularly beneficial for:

Cinema Projection Glass

For an immersive and captivating cinema experience, high-quality projection is paramount. Diamond Coatings’ AR coatings optimise light transmission through the projection screen, ensuring vibrant and high-contrast images for the audience. The consistent performance of Diamond Coatings’ technology guarantees a uniform viewing experience across the entire screen, eliminating any dark spots or inconsistencies.

By minimising unwanted reflections and maximising light transmission, Diamond Coatings’ AR coatings for cinema projection glass elevate the movie-going experience (so the next time you are enjoying your popcorn, think of us!)

ITO Coatings

Indium Tin Oxide (ITO) is another crucial player in the world of optical coatings. It boasts a unique combination of properties: high transparency and electrical conductivity. Diamond Coatings’ technology enables touch screen functionality on displays by allowing electrical signals to pass through while maintaining exceptional clarity for a seamless user experience.

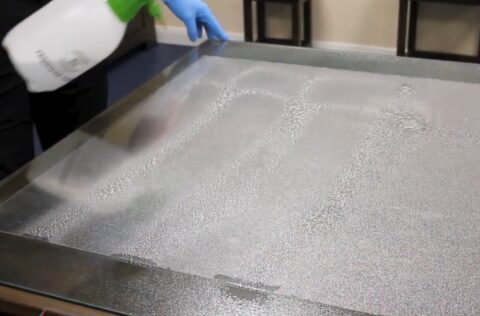

ITO coatings are also used to create electrically heated glass panels, ideal for applications like defogging mirrors or preventing ice buildup on windshields.

If you need assistance with optical coatings and would like to align with an award winning, industry leading company, please get in touch with us today.

At Diamond Coatings, we enhance the capabilities of polyester film by applying our specialised ITO coatings, creating a material that’s truly fit for the future.

At Diamond Coatings, we understand the critical role that projection booth glass plays in delivering a truly immersive cinematic experience

We wanted to highlight the exceptional value now available on our VISIN discounted PPE Face Shields, offering you industry-leading protection and clarity

Have you ever wondered how to achieve crystal-clear visuals and reduce annoying reflections on your displays, windows, or touch panels?

If you are interested in any of our products or services, please use the contact form or give us a call, we will be happy to discuss how we may be able to help you.