Polyester Film UK: The Versatile Solution for Demanding Applications

At Diamond Coatings, we enhance the capabilities of polyester film by applying our specialised ITO coatings, creating a material that’s truly fit for the future.

Innovative and vastly experienced in depositing clear conductive coatings and ITO coatings onto plastic substrates, Diamond Coatings is recognised as a leader in the manufacture of high quality vacuum coatings. Our unique, flexible system for the handling of substrates enables us to deposit conductive coatings onto shaped, injection moulded or flat plastic substrates.

About the Diamox ITO (Indium Tin Oxide) Coating

The transparent, highly conductive ITO coating can be deposited onto plastic substrates or glass. It is used within a broad range of applications, including:

Diamond Coatings supplies ITO coated custom plastic mouldings to large numbers of original equipment manufacturers within electrical and electronic industries throughout Europe, the Far East and the USA.

ITO Coated Custom Plastic Mouldings

Often required to produce ITO Plastic Mouldings including housings; membrane keypads and labels or, as is often the case, a combination of all of these elements in order to facilitate ATEX certification by authorised governing agencies/organisations, we have the ability to deposit ITO sheet resistances of between 10 Ohms/sq. (EMC shielding) and up to 300 Ohms/sq. and above (anti-static requirements).

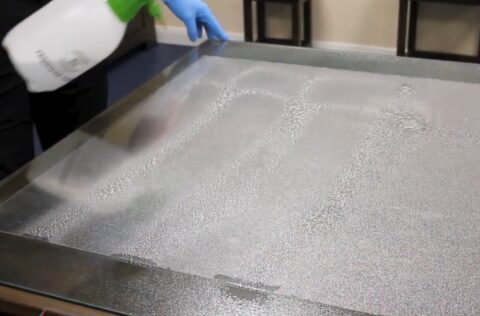

The Process

Having developed and perfected the Diamox ITO coating process, Diamond Coatings has designed and built its own plant for the production of ITO Coated Custom Plastic Mouldings. Carried out in a vacuum at low temperatures, the Diamox process allows coating of glass and a broad variety of plastics, including acrylic, polyester and polycarbonate substrates. The flexible substrate handling system enables coating of flat, curved and varying injection moulded shapes. Diamond Coatings’ plant has the ability to produce ITO Coated Custom Plastic Mouldings of up to 1000 mm by 1000 mm in size with sheet resistances ranging from 8 to 1000 Ohms/sq.

Display Filters

In addition to the application of Diamox ITO coatings to free issue parts, Diamond Coatings can also supply fully machined, finished display filters (acrylic, glass or polycarbonate). Also able to incorporate scratch-resistant and/or anti-glare features, these display components can be screen printed in conductive or standard inks.

At Diamond Coatings, we enhance the capabilities of polyester film by applying our specialised ITO coatings, creating a material that’s truly fit for the future.

At Diamond Coatings, we understand the critical role that projection booth glass plays in delivering a truly immersive cinematic experience

We wanted to highlight the exceptional value now available on our VISIN discounted PPE Face Shields, offering you industry-leading protection and clarity

Have you ever wondered how to achieve crystal-clear visuals and reduce annoying reflections on your displays, windows, or touch panels?

If you are interested in any of our products or services, please use the contact form or give us a call, we will be happy to discuss how we may be able to help you.