Polyester Film UK: The Versatile Solution for Demanding Applications

At Diamond Coatings, we enhance the capabilities of polyester film by applying our specialised ITO coatings, creating a material that’s truly fit for the future.

While the core of Diamond Coatings’ business is based around the sputtering of Indium Tin Oxide (ITO), we have also grown into various industries by continually researching and developing other conductive materials and implementing that research into a production process.

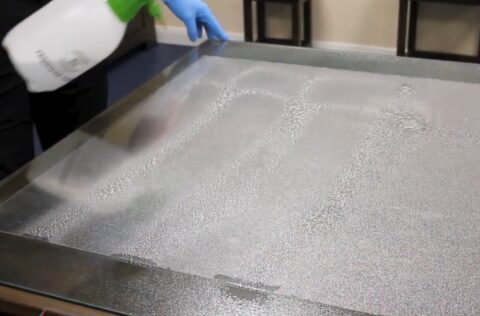

In addition to our vast experience in vacuum coatings, Diamond Coatings have over the past 15 years amassed a wealth of experience in the wet spraying of both conductive and non-conductive paints and materials.

Conductive Materials and Wet Spraying

A sprayed conductive material is often a sufficient option for various applications. It is, however, essential to consider all aspects of adhesion, deposition and conductivity when selecting the most suitable material for any wet spraying solution.

With extensive technical knowledge and experience of conductive materials, Diamond Coatings have custom formulated many conductive paints. Optimised to ensure no cross contamination in materials, these paints are rigorously tested against, to ensure no rusting and fretting corrosion over a long-term period.

By formulating their own conductive paints, Diamond Coatings have ensured the longevity of their solutions, giving the customer peace of mind in the function of their components, which will stand up to the test of time in various conditions.

Diamond Coatings have years of experience in wet spraying various materials such as copper, silver, carbon and nickel, as well as ordinary paints that are simply needed for a cosmetic finish.

Formulation, Development and Customisation of Conductive Paints

With the ability to customise and develop their own formulated paints, Diamond Coatings have seen some of their conductive paint and coating materials certified and approved by the Ministry of Defence. As well as such approvals, Diamond Coatings conductive materials act as an essential feature to various high profile projects and demanding applications.

Having sprayed for so long, Diamond Coatings have comfortably sprayed and supplied in excess of 3 million parts to the military, aerospace and automotive industries and have the capabilities of wet spraying both large and small parts.

Automotive business unit manager Harris Kyriacou said:

“Wet spraying is a particularly challenging and complex production process, because in many cases the conductive paint is an essential feature to the function of the customers’ product.

With wet spraying, there are so many independent variables to be factored in and of course, there is a high natural wastage related to this process, but we have enhanced our robust production system, to remove all variables and reduce the wastage cost, which enables us to offer our customers an extremely competitive price for their wet spraying requirements.

As a company, we always look at the ‘added value’ aspects of any project and try to offer our customers an all-in-one, in house solution, which is why we have a designated spray department, which runs across 3 shifts and sprays on a daily basis, with the capacity to develop this vastly. We focus on really understanding the customers’ requirements for their product and thereafter, custom design and build our own paints and tooling, which enables us to manufacture a repeatable process, from the simplest design to the more intricate, whilst ensuring we maintain the highest of quality standards.

Since 2007, we have sprayed parts for various manufacturers in the automotive industry, including one of the world’s leading and most recognised luxury car manufacturers and consistency is essential in the supply to the automotive industry. We currently spray in the region of 1 million parts per year for this manufacturer and have recently had our involvement in this project extended till at least 2025. With the forecasted figures, we anticipate this annual wet spraying figure to increase drastically year on year”.

Contact Us

Please feel free to contact us to discuss your wet spraying requirements. Diamond Coatings will be more than happy to assist you in moving your project forward – be it of functional or cosmetic purpose – no matter what stage of development you are at.

At Diamond Coatings, we enhance the capabilities of polyester film by applying our specialised ITO coatings, creating a material that’s truly fit for the future.

At Diamond Coatings, we understand the critical role that projection booth glass plays in delivering a truly immersive cinematic experience

We wanted to highlight the exceptional value now available on our VISIN discounted PPE Face Shields, offering you industry-leading protection and clarity

Have you ever wondered how to achieve crystal-clear visuals and reduce annoying reflections on your displays, windows, or touch panels?

If you are interested in any of our products or services, please use the contact form or give us a call, we will be happy to discuss how we may be able to help you.