Polyester Film UK: The Versatile Solution for Demanding Applications

At Diamond Coatings, we enhance the capabilities of polyester film by applying our specialised ITO coatings, creating a material that’s truly fit for the future.

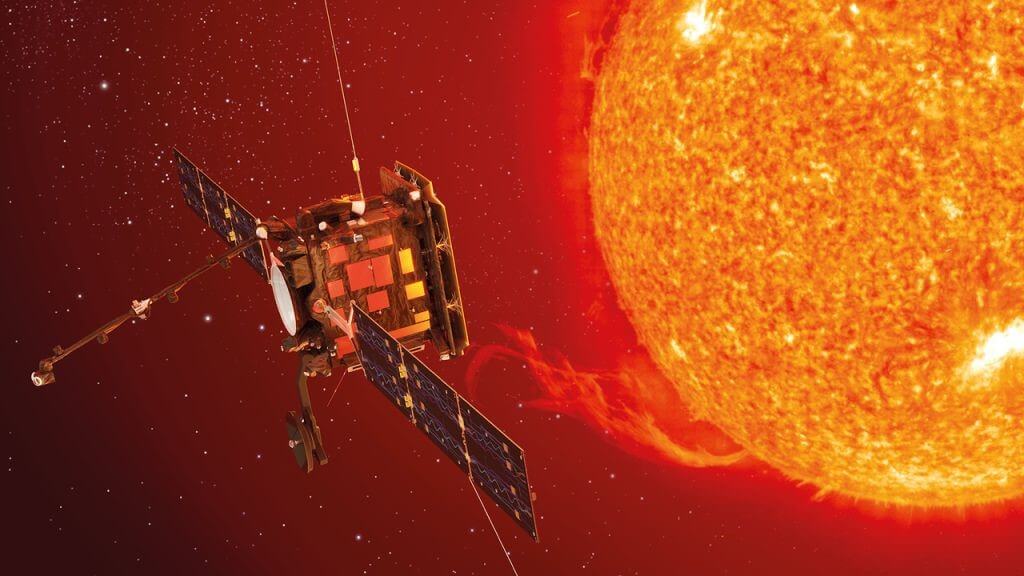

The Solar Orbiter is a European Space Agency led mission working closely with NASA to observe and explore the Sun, its solar winds and how they affect our planet, as well as providing the first ever images of the Polar regions, an area of which there is little understanding currently.

The Solar Orbiter is a European Space Agency led mission working closely with NASA to observe and explore the Sun, its solar winds and how they affect our planet, as well as providing the first ever images of the Polar regions, an area of which there is little understanding currently.

Although it won’t get as close to the Sun as the NASA Parker Probe, it will still be in a Sun-facing orbit over its entire life, imaging and measuring the Solar environment through instrument ports at the front of the heat shield. The craft will encounter sunlight 13 times more powerful than that of the Earth’s orbit and will offer unprecedented views of the Sun.

It’s going to be HOT!

With spacecraft you think ‘white’, with sun, you think ‘avoid black’… With the Solar Orbiter, things needed to be mixed up a little. Under extreme UV and temperatures, white coatings slowly change colour and this would affect the ability to keep cool.

The spacecraft has had to be coated in a pigment created from bone. The resulting carbon/ceramic is highly durable, and has been shown to be incredibly stable under UV and temperature cycling.

It also allowed for a white silicate layer to be applied as an overcoat. The dense ceramic coating needed a stable interface to compensate for the thermal expansion difference between the hot aluminium on the inward face of the panels on the craft and the cold vacuum of space on the white coated side.

It also allowed for a white silicate layer to be applied as an overcoat. The dense ceramic coating needed a stable interface to compensate for the thermal expansion difference between the hot aluminium on the inward face of the panels on the craft and the cold vacuum of space on the white coated side.

The initial SolarWhite coating was co-developed between ENBIO and University College Dublin in Ireland. However, as a number of the SolarWhite components were not sun facing, they would reach temperatures as low as -120°C. At these temperatures, surface conductivity of ceramics decreases and causes a potential risk for charging and eventually an electrostatic discharge that could jeopardise an electrical system on the craft.

ENBIO’s CTO, Barry Twomey said “without the help of Diamond Coatings and their application of the conductive ITO coating on the SORA (Stood-Off Radiator Assembly) panels, the SolarWhite coating would not have performed as intended, putting key instruments at risk. The collaboration was facilitated by Diamond Coating’s flexibility and willingness to support us with our tight deadlines and the scrutiny that goes with such a big project”.

Although the conductive coating is < 1 µm, it has a big impact on the performance of this white new coating.

This video has a nice view of the work we did for ENBIO and The European Space Agency.

https://www.esa.int/Science_Exploration/Space_Science/Solar_Orbiter

At Diamond Coatings, we enhance the capabilities of polyester film by applying our specialised ITO coatings, creating a material that’s truly fit for the future.

At Diamond Coatings, we understand the critical role that projection booth glass plays in delivering a truly immersive cinematic experience

We wanted to highlight the exceptional value now available on our VISIN discounted PPE Face Shields, offering you industry-leading protection and clarity

Have you ever wondered how to achieve crystal-clear visuals and reduce annoying reflections on your displays, windows, or touch panels?

If you are interested in any of our products or services, please use the contact form or give us a call, we will be happy to discuss how we may be able to help you.