Polyester Film UK: The Versatile Solution for Demanding Applications

At Diamond Coatings, we enhance the capabilities of polyester film by applying our specialised ITO coatings, creating a material that’s truly fit for the future.

Which is better – Resistive or Capacitive Touch Screens?

If you are looking for a clear-cut answer to the above, sorry – it’s not that simple… (but it’s capacitive in our book). Both forms of touchscreens are good at certain things in certain environments, but maybe that doesn’t make either one better (unless it’s a capacitive screen).

You may have spotted we have a favourite among the two options, but this is only because we (and you) most likely use a capacitive touch screen daily.

Resistive and Capacitive – What’s the difference?

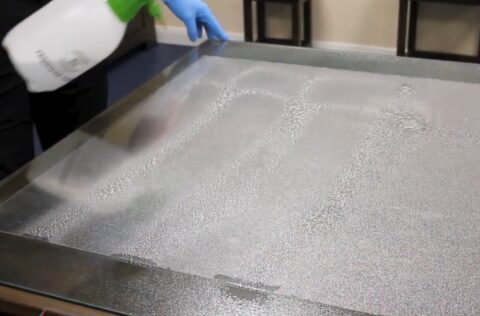

In simple forms, it is in the name. A resistive touchscreen uses resistance in the form of minor downward pressure on a screen. A resistive screen has two layers, a hard plastic or glass top layer and a bottom layer that conducts charge. The 2 layers are separated with spacers and when pressure is applied there is a change in charge in that location, which allows the software to recognise point of contact (touch).

A capacitive touchscreen works differently. The glass on a touchscreen is usually coated with ITO (Indium Tin Oxide), which is both transparent and conductive. Beneath the screen in 4 corners, there is usually four electrodes which maintain a voltage across the glass. When you touch the glass, sensors detect the change in voltage and can determine precise positions. Your own physical touch has altered the voltage as we are naturally conductive.

Resistive and Capacitive Touch Screens… Which is better?

We deliberately said positions as plural in last paragraph because this is where capacitive screens come into their own. Multiple touches, swipes and pinches can be detected with capacitive touch screens. Resistive screens generally can register one command at any given time.

This is why most smartphones and tablets use capacitive screens. There is an added benefit of better clarity than that of resistive screens (which utilise the two layers causing a loss of image quality on screen).

However, resistive touchscreens have their place, and we probably couldn’t live without them. Generally, they are more robust than capacitive screens which makes them ideal for use in public facing environments as well as military and medical environments.

Resistive touchscreens can also be used whilst wearing gloves. For military and medical, that can be vital. We were joking at the start of this article – capacitive screens are not better, we think both types of touchscreen are equal in terms of what they do and how they benefit the world we live in, in differing ways.

Resistive and Capacitive Touch Screens Supplier

We can provide both capacitive and resistive touch screens, from development to production volumes, and in sizes ranging up to 1m x 1m. The screens can be provided with anti-glare and other finishes as required, and produced on glass or plastic (flexible or rigid).

If you would like to know more about our touchscreens, please get in touch with us today to discuss your specific requirements.

At Diamond Coatings, we enhance the capabilities of polyester film by applying our specialised ITO coatings, creating a material that’s truly fit for the future.

At Diamond Coatings, we understand the critical role that projection booth glass plays in delivering a truly immersive cinematic experience

We wanted to highlight the exceptional value now available on our VISIN discounted PPE Face Shields, offering you industry-leading protection and clarity

Have you ever wondered how to achieve crystal-clear visuals and reduce annoying reflections on your displays, windows, or touch panels?

If you are interested in any of our products or services, please use the contact form or give us a call, we will be happy to discuss how we may be able to help you.