Polyester Film UK: The Versatile Solution for Demanding Applications

At Diamond Coatings, we enhance the capabilities of polyester film by applying our specialised ITO coatings, creating a material that’s truly fit for the future.

The borosilicate glass sheet UK coating specialists Diamond Coatings offer as a substrate for diverse ITO and other coatings offers properties beneficial to numerous industries’ applications. Here is what these properties and applications are…

A colourless, clear low soda glass, borosilicate glass consists primarily of silica, boric oxide, sodium oxide, potassium oxide and calcium oxide (70%, 10%, 8%, 8% and 1% respectively). It is produced by melting these components together. As the transition temperature of these materials ranges up to 560° C, the melting process requires significantly higher temperatures than those necessary to make traditional glass.

While this makes borosilicate glass somewhat more difficult and consequently slightly more expensive to produce, its superior durability and properties serve to still make it an economical choice both in terms of production and use.

Boasting a low thermal expansion coefficient of 3.2 x 10-6 1/K, Knoop hardness (at 20° C) of 400 – 480, and a 2650 – 27000 MPa Shear modulus, borosilicate glass not only maintains its integrity when exposed to thermal shocks that would cause other types of glass to deform or warp but is also able to withstand blunt force impacts better than other glass types.

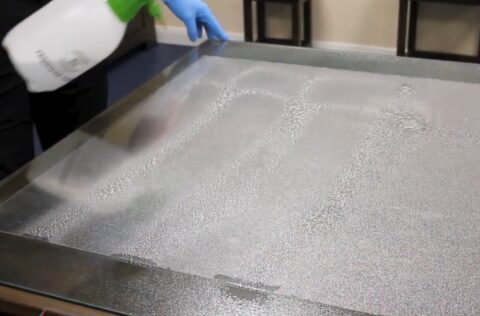

Highly resistant to acid mixtures, acid & neutral solutions and concentrated acids; chlorine, iodine and bromine; water and organic substances, it also has superior chemical resistance to most metals and other materials even when exposed for prolonged periods at temperatures greater than 100° C.

Then, of course, there are its optical properties: borosilicate is a so-called crown glass with negligible absorption in the spectral (approximately 310nm to 2,200nm) range, low dispersion and comparatively low refractive indices (1.51 to 1.54) across the range of visible light.

Combining these properties with premium-quality indium tin oxide coatings makes borosilicate glass the perfect choice for applications including, to name just a few:

We can provide borosilicate glass sheets (and indeed all our glass substrates):

To learn more about our coating options for borosilicate/other substrates and/or to discuss any specific requirements for your application, please get in touch with our technical experts, who will be happy to advise and assist you.

At Diamond Coatings, we enhance the capabilities of polyester film by applying our specialised ITO coatings, creating a material that’s truly fit for the future.

At Diamond Coatings, we understand the critical role that projection booth glass plays in delivering a truly immersive cinematic experience

We wanted to highlight the exceptional value now available on our VISIN discounted PPE Face Shields, offering you industry-leading protection and clarity

Have you ever wondered how to achieve crystal-clear visuals and reduce annoying reflections on your displays, windows, or touch panels?

If you are interested in any of our products or services, please use the contact form or give us a call, we will be happy to discuss how we may be able to help you.