Polyester Film UK: The Versatile Solution for Demanding Applications

At Diamond Coatings, we enhance the capabilities of polyester film by applying our specialised ITO coatings, creating a material that’s truly fit for the future.

As of the 20th of April ’16, new ATEX regulations necessitate the protection of devices and equipment used in safety critical working environments/applications against static electricity/electrostatic charges that have the potential to cause dangerous discharges. Measures to provide this protection include, among others, application of an anti-static coating.

What Devices Do the New ATEX Regulations Apply to?

Devices/equipment to which these new directives apply include any devices/pieces of equipment that have effective internal ignition sources and are intended for use under normal conditions (atmospheric) within potentially dangerous and explosive atmospheres.

Membrane Keyboards

Membrane keypads, keyboards or switches are designed to provide total reliability in often extremely hostile environments. As such, membrane keypads must also be fully compliant with ATEX standards.

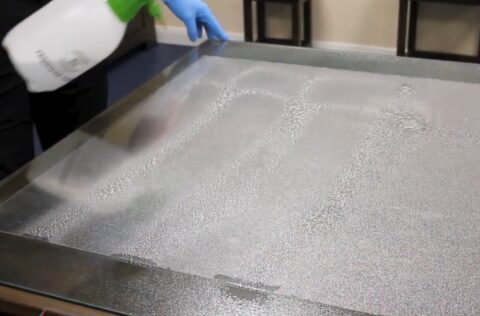

Diamond Coatings Anti-Static Coating

We specialise in depositing ITO Anti-Static Coatings onto membrane keyboards/keypads; graphic overlays, name plate and/or labels of varying shapes, sizes and designs. Working in close-cooperation with customers in many industries requiring information display and human interface control solutions for hostile working environments and/or safety critical applications, we can assure ATEX compliance with our vacuum deposited clear anti-static coating.

Industries

Using our advanced vacuum coating technology and industry leading clear anti-static coatings, we assist customers in achieving ATEX compliance in a variety of industries including, for example:

We do, for example, already work on clear anti-static coating solutions with an international company supplying membrane keypads/keyboards; graphic overlays, system serial and rating labels and more to clients in medical, fire and security; catering, instrumentation control and military; rail, aviation and marine industry sectors. Every application of our vacuum deposited clear anti-static coating, from simple labels to custom-designed mouldings, has passed client-conducted safety tests.

Learn more

You can learn more about what we do and how we do it and/or discuss your company’s specific anti-static coating requirements by speaking to one of our ITO coating experts on Tel.: +44 (0) 121 550 9430 now.

At Diamond Coatings, we enhance the capabilities of polyester film by applying our specialised ITO coatings, creating a material that’s truly fit for the future.

At Diamond Coatings, we understand the critical role that projection booth glass plays in delivering a truly immersive cinematic experience

We wanted to highlight the exceptional value now available on our VISIN discounted PPE Face Shields, offering you industry-leading protection and clarity

Have you ever wondered how to achieve crystal-clear visuals and reduce annoying reflections on your displays, windows, or touch panels?

If you are interested in any of our products or services, please use the contact form or give us a call, we will be happy to discuss how we may be able to help you.