Say Goodbye to Glare: The Essential Garmin Nav 6 Anti-Reflective Film

With the Garmin Nav 6 Anti-Reflective Film, you can say goodbye to shading a screen in harsh sunlight

Anti-glare vs anti-reflective – What is the difference?

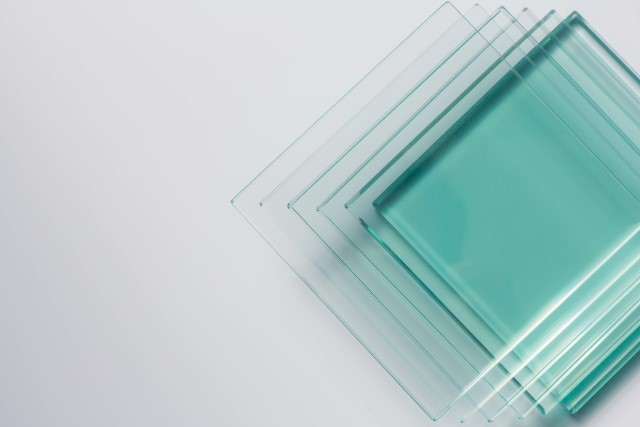

So, you’re looking to improve clarity and reduce glare on your glass surfaces, but terms like “anti-glare” and “anti-reflective” leave you confused. Don’t worry, you’re not alone!

While these terms are often used interchangeably, they represent distinct technologies with varying applications. At Diamond Coatings, we produce and supply high-performance anti-reflective coatings, and we’re here to set the record straight.

Both anti-glare and anti-reflective coatings address the issue of unwanted reflections on glass. These reflections can cause several problems:

Now, let’s explore the approaches these coatings take to combat glare:

Anti-glare:

Anti-reflective (AR):

Diamond Coatings Anti-reflective Technology

At Diamond Coatings, we champion the power of anti-reflective technology. We offer a range of high-performance AR coatings, including:

Diamond Coatings offer premium quality, high-performance anti-reflective solutions. Contact us today to discuss your specific needs and discover how our innovative coatings can enhance your vision and unlock the true potential of your glass surfaces.

We’re committed to helping you see the world with exceptional clarity, free from distracting glare.

With the Garmin Nav 6 Anti-Reflective Film, you can say goodbye to shading a screen in harsh sunlight

At Diamond Coatings, we provide the foundational transparent conductive coatings that make these advanced switches possible

At Diamond Coatings, we specialise in turning ordinary glass into high-performance heated windows

As a leading name among ITO companies, Diamond Coatings doesn’t just supply standard coatings; we engineer bespoke solutions that push boundaries

If you are interested in any of our products or services, please use the contact form or give us a call, we will be happy to discuss how we may be able to help you.