Say Goodbye to Glare: The Essential Garmin Nav 6 Anti-Reflective Film

With the Garmin Nav 6 Anti-Reflective Film, you can say goodbye to shading a screen in harsh sunlight

Acrylic Hard Coating

There is a common school of thought that acrylic is far superior to standard glass. This could be a correct statement, but it depends on the usage of either, perhaps. Acrylics are lighter than glass which comes with obvious benefits, from transportation to fitting.

It could also be said that acrylic is the best of all plastics, but again this is based on the application.

Polycarbonates are tougher than acrylics, but they are considered inferior optically. Wouldn’t it be great if there was a way of ‘toughening up’ acrylics? Oh, wait…

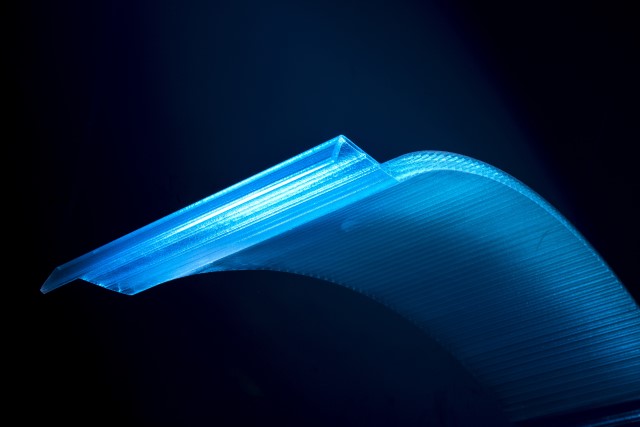

Acrylic Hard Coating

A hard coated acrylic? Now you’re talking! At Diamond Coatings we offer a range of coatings (the clue is in the company name, after all!), including ITO (Indium Tin Oxide) coatings, anti reflective coatings and of course, hard coatings. We have the ability to coat glass and plastics including polycarbonates and acrylics.

One such acrylic coating is DIA.HC-KRF Hard-Coat providing high scratch resistance and hardness, combined with improved weather and chemical resistance.

This resistive coating protects the acrylic from scratches and general wear as well as protecting the cosmetic quality and appearance of the plastic. DIA.HC-KRF is suitable for acrylic and PMMA substrates.

Why would you need an acrylic hard coating?

Acrylic is reasonably robust (to a point, but everything has a breaking point), with acrylic usage in the public domain is high. The public domain can also equate to a tough environment, especially those that are either heavy handed, or clumsy, or both…

At Diamond Coatings, our acrylic substrates are hand-made and inspected to exceptionally high optical specifications. We can also offer anti reflective coatings to enhance the acrylic hard coating further – this is a perfect solution for any display acrylic – it’s tough and offers great clarity.

Where would you need an acrylic hard coating?

As mentioned above, anywhere in the public domain using acrylic in whatever form would benefit from using a hard coating to prolong the lifetime of said acrylic. The most obvious application would be at point of sale in a retail environment, but it isn’t limited to just that area.

The automotive and aerospace industry utilise acrylic with hard coatings within different applications. Safety glazing is another use for hard coated acrylic, along with display screens and even camera lenses. If acrylic is being used and it is within a testing environment, then a hard coat option should always be considered.

If you would like to know more about our acrylic hard coating service or you have a specific enquiry relating to your own requirements, we would be very happy to hear from you. Contact us today – a member of the team will respond as soon as possible.

With the Garmin Nav 6 Anti-Reflective Film, you can say goodbye to shading a screen in harsh sunlight

At Diamond Coatings, we provide the foundational transparent conductive coatings that make these advanced switches possible

At Diamond Coatings, we specialise in turning ordinary glass into high-performance heated windows

As a leading name among ITO companies, Diamond Coatings doesn’t just supply standard coatings; we engineer bespoke solutions that push boundaries

If you are interested in any of our products or services, please use the contact form or give us a call, we will be happy to discuss how we may be able to help you.