Say Goodbye to Glare: The Essential Garmin Nav 6 Anti-Reflective Film

With the Garmin Nav 6 Anti-Reflective Film, you can say goodbye to shading a screen in harsh sunlight

Why you need electrically conductive plastics

Electrically conductive plastics have revolutionised the way we interact with technology. These innovative materials seamlessly combine the electrical conductivity of metals with the flexibility and durability of plastics, opening up a world of possibilities across various industries.

Understanding Electrically Conductive Plastics

Electrically conductive plastics are a class of materials that possess the ability to conduct electricity. Unlike traditional plastics, which are typically insulators, these materials have been modified to incorporate conductive elements, such as carbon nanotubes, silver nanoparticles, or conductive polymers.

This enhancement enables them to serve as efficient electrical conductors while retaining the desirable mechanical properties of plastics, such as flexibility, lightweight nature, and ease of processing.

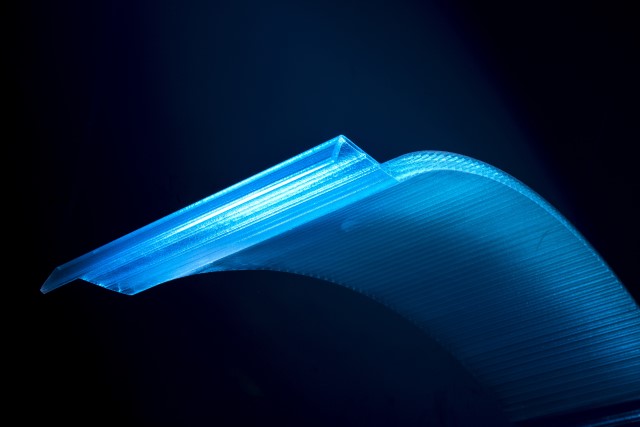

The Rise of ITO Coated Plastic

Among the various types of electrically conductive plastics, ITO (Indium Tin Oxide) coated plastic has gained significant prominence. ITO is a transparent conductive oxide (TCO) material that offers exceptional electrical conductivity, high optical transparency, and excellent chemical stability. When applied as a coating on plastic substrates, ITO imparts conductive properties while maintaining the plastic’s flexibility and transparency.

Properties and Benefits of ITO Coated Plastic

Diverse Applications of ITO Coated Plastic

The versatility of ITO coated plastic has led to its adoption in a wide range of industries and applications. Here are some common uses:

Electrically conductive plastics, particularly ITO coated plastic, have revolutionised various industries by offering a unique blend of electrical conductivity and mechanical flexibility. Their diverse applications, ranging from electronic displays to solar cells, demonstrate their immense potential.

As an industry leader in electrically conductive coatings for glass, thin PET films, and plastic, Diamond Coatings is committed to providing high-quality solutions that meet the demanding requirements of today’s applications. Our expertise and state-of-the-art facilities enable us to deliver tailored coatings that enhance the performance and functionality of your products.

To learn more about how Diamond Coatings can help you harness the power of electrically conductive plastics, contact us today.

With the Garmin Nav 6 Anti-Reflective Film, you can say goodbye to shading a screen in harsh sunlight

At Diamond Coatings, we provide the foundational transparent conductive coatings that make these advanced switches possible

At Diamond Coatings, we specialise in turning ordinary glass into high-performance heated windows

As a leading name among ITO companies, Diamond Coatings doesn’t just supply standard coatings; we engineer bespoke solutions that push boundaries

If you are interested in any of our products or services, please use the contact form or give us a call, we will be happy to discuss how we may be able to help you.