Custom Diamox Indium Tin Oxide (ITO) Coating

Capability

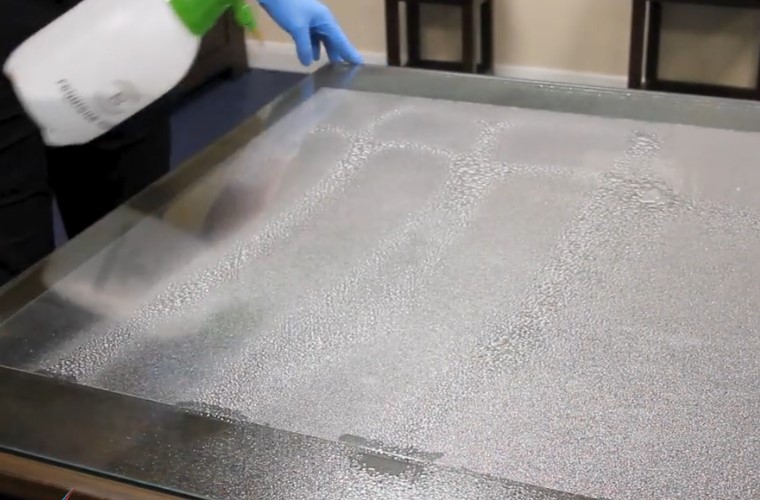

DIAMOX Indium tin oxide (ITO) coatings are produced by low temperature vacuum deposition. The ITO is a highly conductive transparent coating and is available deposited on to glass or plastic substrates including polycarbonate, acrylic and polyester. A flexible system for handling the substrate enables both flat and shaped, as well as a range of injected moulded parts, to be coated.

DIAMOX ITO coatings are available with a sheet resistance from 2.5 – 1500ohms/square in sheet sizes up to 1000mmx1000mm. Diamond can supply fully machined glass and plastic parts and also provides an ITO coating service for free issue parts.

The DIAMOX coating can be etched to produce fine conductor paths.

Product Information

DIAMOX ITO Coating Product Information

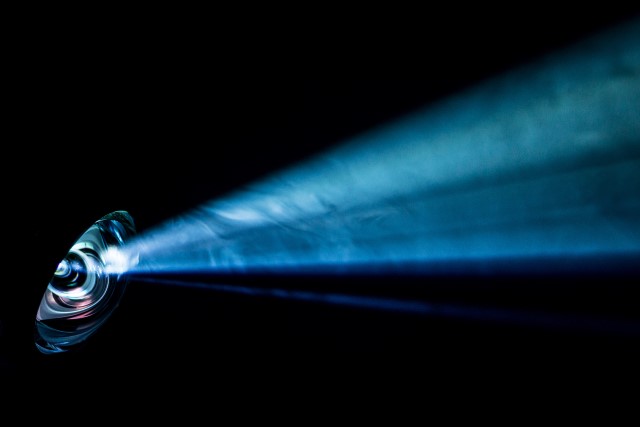

The typical peak light transmission, in the wavelength range 525 to 600nm, for a 20ohm/sq coating on glass is 87% and on polycarbonate 81%.

Durability

There is no evidence of optical degradation or a reduction in ITO coating adhesion or sheet resistance when DIAMOX coatings have been subjected to Thermal Cycling, Salt Spray and Humidity Cycling (To MIL STD 48497).

EMI/RFI Shielding Effectiveness

Using test methods consistent with MIL-STD-215, DIAMOX ITO offers a shielding effectiveness up to 58dB at 1MH and 26dB at 1GH.

Applications

- Electromagnetic Interference (EMI)/ Radio-Frequency (RFI) Shielding

- Resistive and Capacitive Touch Panels

- Optical Clear Heated Display Filters

- Photovoltaic Cells

- Electrostatic Dissipation

Transmission Graphs

Diamond Coatings produce a vast range of ITO, Index Matched & Multi-Layer Anti-Reflection Coatings – many of which are designed specifically to meet customers optical requirements, we can provide transmission & reflection graphs for all of our optical coatings.

If you have specific optical requirements please contact us and our technical team can design and recommend a coatings solution that will best meet the criteria for your application.