Say Goodbye to Glare: The Essential Garmin Nav 6 Anti-Reflective Film

With the Garmin Nav 6 Anti-Reflective Film, you can say goodbye to shading a screen in harsh sunlight

Applications Of Electrically Conductive Plastic

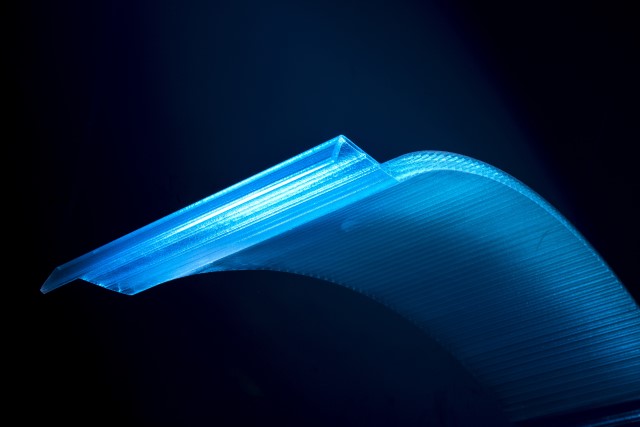

At Diamond Coatings, we’re driven by a constant pursuit of innovation. We explore the frontiers of materials and techniques, pushing the boundaries of what’s possible. One particularly exciting area is the use of electrically conductive plastics.

These unique materials bridge the gap between the versatility of plastic and the conductivity of metals, paving the way for a new generation of lighter, more flexible products.

But what exactly are electrically conductive plastics, and what makes them so groundbreaking? Let’s take a closer look at electrically conductive plastics and explore how Diamond Coatings utilises Indium Tin Oxide (ITO) coating technology to unlock their potential.

ITO Coatings and Conductive Plastic

Electrically conductive plastics aren’t born with their conductivity – it’s strategically added. Here at Diamond Coatings, we specialise in using Indium Tin Oxide (ITO) coatings. ITO is a transparent material renowned for its exceptional electrical conductivity and optical properties.

Our meticulous process involves depositing a thin layer of ITO onto the plastic substrate using a specialised sputtering technique. This creates a uniform, adherent coating that grants the plastic conductive properties without sacrificing its advantages, such as lightweight design and superior formability.

Conductive Plastic Applications

The unique properties of conductive plastic make it a game-changer for a vast array of applications. Here are some key areas where conductive plastic shines:

Electrostatic Discharge (ESD) Protection: Conductive plastics excel at dissipating static electricity, making them the perfect shield for applications where ESD poses a threat to sensitive electronics. Imagine packaging for circuit boards or components in electronic devices – conductive plastics effectively prevent static build-up, safeguarding delicate circuitry.

Electromagnetic Interference (EMI) Shielding: ITO-coated plastics form effective barriers against electromagnetic interference, which is crucial for protecting electronic devices from external noise. This ensures proper functioning and prevents malfunctions caused by stray electromagnetic signals.

Flexible Electronics: The lightweight and flexible nature of conductive plastics makes them ideal for the next generation of wearable and flexible electronics. Imagine touchscreens seamlessly integrated into clothing or bendable displays for mobile devices – conductive plastics pave the way for these innovative possibilities.

Lightweight Construction: Conductive plastics can replace heavier metal components in various industries, including automotive and aerospace. This translates to lighter vehicles and aircraft, leading to improved fuel efficiency and overall performance.

Sensor Technology: The conductive properties of these plastics make them well-suited for use in various sensors. Imagine sensors that detect touch, pressure, and even temperature – conductive plastics are instrumental in developing these innovative sensing technologies.

These are just a glimpse into the vast potential of conductive plastics. As the technology matures and production costs decrease, we can expect to see them revolutionise various industries. From medical devices with enhanced functionality to consumer electronics with improved flexibility, the possibilities are truly endless…

Diamond Coatings: Your Partner in Conductive Plastic Innovation

At Diamond Coatings, we are at the forefront of ITO coating technology. We offer a comprehensive range of conductive plastic solutions tailored to your specific needs. Our team of experts are dedicated to guiding you through the exciting world of conductive plastics and helping you integrate them seamlessly into your next project.

Ready to explore the potential of conductive plastics and bring your innovative ideas to life? Contact Diamond Coatings today and let’s embark on this journey together.

With the Garmin Nav 6 Anti-Reflective Film, you can say goodbye to shading a screen in harsh sunlight

At Diamond Coatings, we provide the foundational transparent conductive coatings that make these advanced switches possible

At Diamond Coatings, we specialise in turning ordinary glass into high-performance heated windows

As a leading name among ITO companies, Diamond Coatings doesn’t just supply standard coatings; we engineer bespoke solutions that push boundaries

If you are interested in any of our products or services, please use the contact form or give us a call, we will be happy to discuss how we may be able to help you.