Diamond Monolithic Filters

Capability

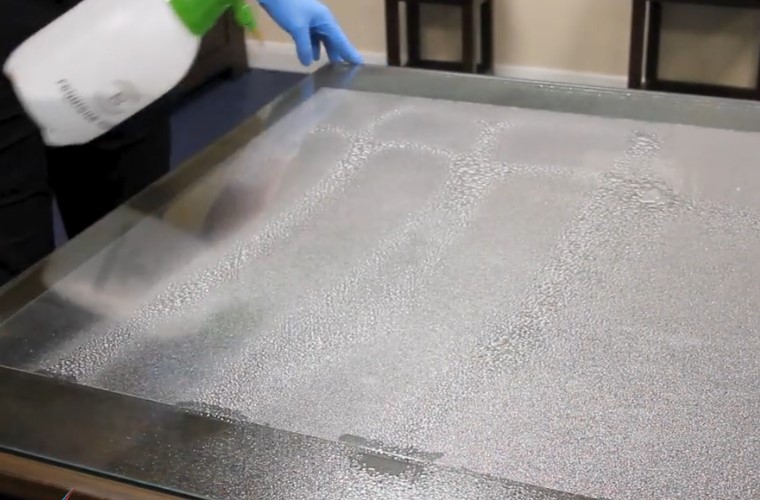

DIAMOND monolithic filters are custom designed flat or profiled RFI Shielded Optical Filters produced by depositing a thin electrically conductive transparent coating directly onto the substrate.

DIAMOND monolithic RFI filters are available on a wide range of substrates including glass, polycarbonate and acrylic with different surface finishes including DIAMOX+ anti-reflection coating, etched glass and non-glare hard coatings for plastic substrates. The coatings are available with a sheet resistance from 10 ohms/sq and in sizes up to 1000mmx1000mm.

Product Information

Monolithic Filters – Properties

EMI/RFI Shielding Effectiveness of DIAMOND’s Filters, measured using independent test methods consistent with MIL-STD-285, range from 58dB at 1MHz to 26dB at 1Ghz.

Spectral light transmissions will depend on the nature and surface finish of the substrate. For 20 ohm/sq coating on glass the transmission ranges from 87% for the standard DIAMOX coating to 92% for the indexed matched DIAMOX coating.

For a clear hard coated polycarbonate, the light transmission for a 50ohm/sq coating is 85% for the standard DIAMOX coating and 89% for DIAMOX+ coating.

The above are typical peak light transmissions in the wavelength range 525 to 600nm.

Termination

DIAMOND monolithic filters can be terminated with copper tapes or silver bus bar that can be carried around to the front surface. Conductive silicone gaskets and fabric over foam gaskets can also be used.

Advantages of Diamond’s RFI Filters

- Highly conducting resulting in attenuation of 58dB at 1MHz to 26dB at 1GHz.

- Excellent light transmission, standard DIAMOX grade typically 87% and index matched DIAMOX+ grade 92%.

- Wide range of substrate materials available including glass, polycarbonate and acrylic.

- Available as monolithic flat and profiled filters with improved environmental and mechanical stability over edge bonded and laminated filters.